(Image Courtesy:http://en.wikipedia.org/wiki/File:Six_sigma-2.savg & http://www.flickr.com/photos/purpleslog/2870445256/)

SIX SIGMA IN INFORMATION SECURITY:

TOOL TO RESOLVE PROBLEMS IN INFORMATION SECURITY/TECHNOLOGY MANAGEMENT

(Image Courtesy:http://en.wikipedia.org/wiki/File:Six_sigma-2.savg & http://www.flickr.com/photos/purpleslog/2870445256/)

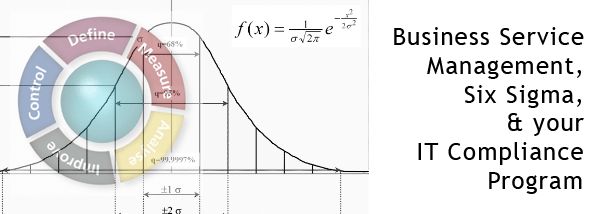

Originally developed by Motorola in 1986, six sigma methodologies, few years back was believed to be one of the best tools to achieve the production target with the minimum DPM of 3.4 or to increase process capability of any process, in any manufacturing industry. Six Sigma is basically a statistical approach which has six standard deviations on both side of the specification window. Completely driven by data, an approach that helps to find out number of defects that a system is producing. But it's not just a statistical method but a completely changed way of looking at the problem. An approach that enables you to look deep in to the problem finding the exact root cause.

Now days, six sigma has acquired a new meaning, it's not at all a statistical problem solving approach now, but a philosophy of leading a completely changed industrial life. It all started from reducing defects, making process cost effective, adding value to the processes and the organisation and now have come to having personal developments i.e. now, six sigma application means to change mind set completely and adopting a new way of problem solving which is more practical, which focuses more on real time encounters with problems.

The major problem solving approaches of SIX SIGMA can efficiently be applied in any field; Information security management is one of them. The major examples include the Raytheon aircraft IT department which saves 13million $ of their company by introducing SIX Sigma to their processes.

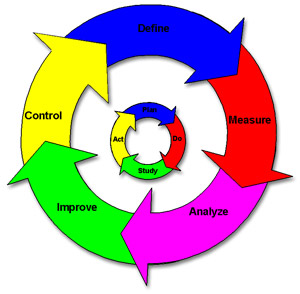

Six Sigma and its tools including various problem solving approaches which includes PDCA, DMAIC, DMADV can help to minimize errors in data, the processing time, standarizing the process which is currently being followed in the organisation, reducing the processing time and making savings from them.

Various data presenting tools including Pareto charts, Control charts,Histogrms,Ishikawa diagrams can help to hit the target immediately instead of other ways of data presentation where u have to mail it to various management peoples and they come to their decisions and then solutions begun to be searched.

In a recent interview "Seagate Technologies" Senior Vice President & CIO Mark.A.Brewer said: "If I view IT operations as a factory, then Six Sigma applies immediately. I have a factory; it's just data centres, networks, servers, VPN, help desks and so on"

(Ref:http://www.cio.com/article/29626/_Quality_Methodology_Six_Sigma_Comes_to_IT)

According to him" Six Sigma is about taking your IT organization and getting it under control"

And it should not be taken lightly that they saved 3.7 million$ during last fiscal year and 4.5 million $ as a whole after investing six sigma two years ago, this earning was from IT department only where as Sea Gate is mainly a manufacturing firm.

One of the major problem solving approaches in Six Sigma include DMAIC: